Rainflow

The Integral / Rainflow software allows pipeline operators to monitor pressure cycle fatigue and manage cracks and dents. The software is capable of handling years of pressure data recorded at minute resolution and performs detailed pressure cycle counting and remaining life assessments in seconds. The results are summarized on a monthly basis to enable continuous monitoring of fatigue and crack growth.

The software uses PRCI MAT-8, the most accurate fracture mechanics model available, to establish the largest potential surviving flaws after a hydrostatic test (or mill test) and to calculate the expected time to failure of these and any measured cracks.

The analysis methodologies in the Integral / Rainflow software are consistent with API RP 1176 for crack management and API RP 1183 for dent management.

Pressure Cycle Counting

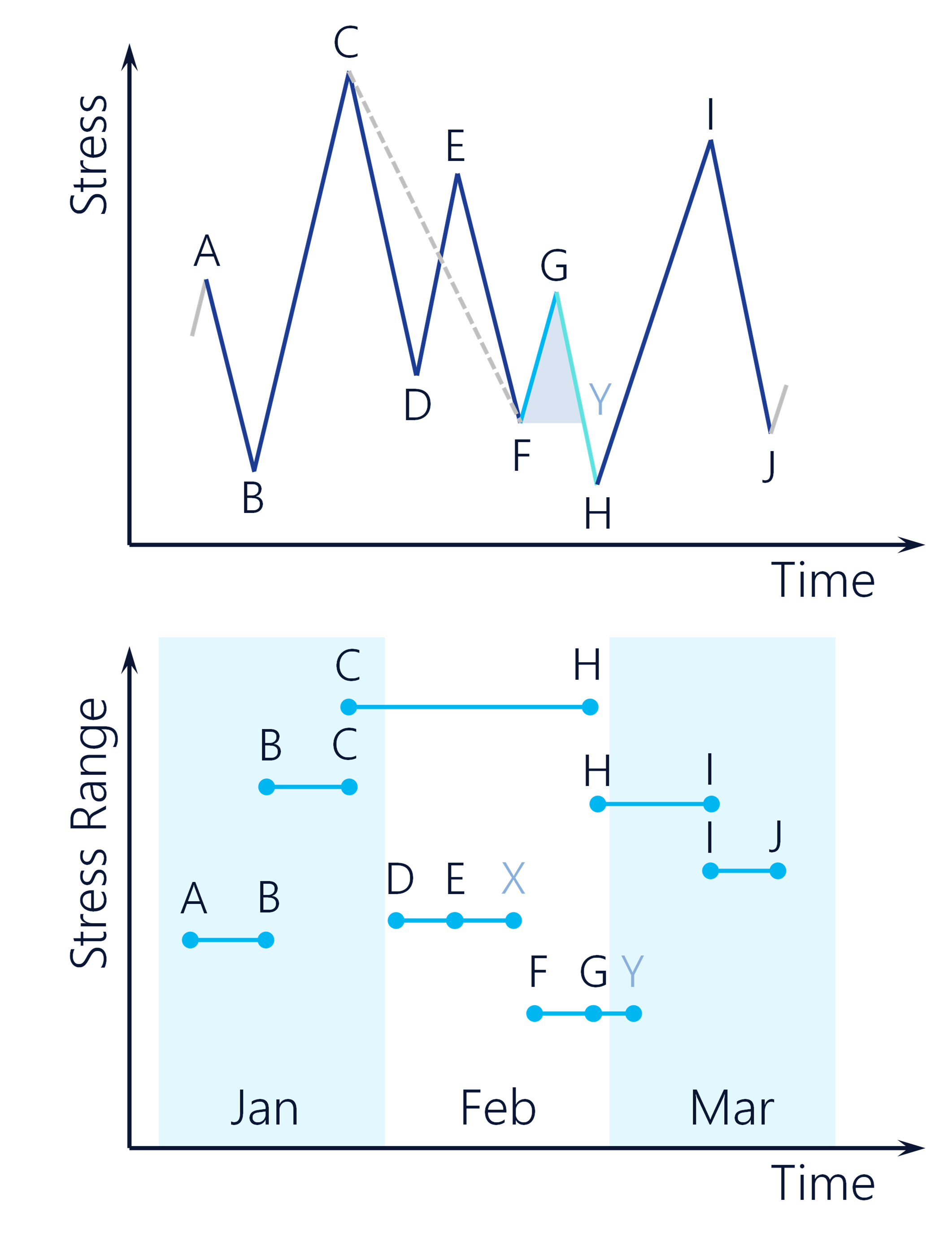

The Integral / Rainflow app uses the rainflow counting algorithm described in ASTM E 1049 Standard Practices for Cycle Counting in Fatigue Analysis. This method is the most commonly used in the pipeline industry. Our implementation has the following features:

Filters out small oscillations and noisy signal data that do not contribute to fatigue damage

Pro-rates the fatigue cycles across monthly intervals

Dynamically summarizes the results into a histogram with user-defined bin widths

Removes cycles that do not meet a threshold stress intensity to cause crack growth

Generates charts and data summaries showing every pressure cycle over time and histograms of cycle pressure ranges.

Summarizes the pressure cycles into equivalent annual cycle counts for each month of data using Miner’s rule and the Paris Law for crack growth. The metrics include:

PHMSA TTO-5 category

Spectrum Severity Indicator (SSI)

Cyclic Index (CI)

Remaining Life Assessment

The curve describing the combinations of lengths and depths of the largest potential surviving cracks following a hydrotest is known as the critical flaw curve. The Integral / Rainflow software calculates these curves using the PRCI MAT-8 model and accounts for the specific pressure history of each pipeline segment.

The minimum time taken for any flaw on the hydrostatic test curve to reach a critical size is calculated using the historical pressure cycle loading to date and a projected future cyclic loading. In the absence of any recent or planned pressure tests, a mill test at the time of manufacture or a hydrostatic test during construction and commissioning can be used as the pressure test condition.

Measured cracks and dents on the pipeline are analyzed using the fatigue loading at the location of the crack, dent or pipe segment, accounting for frictional losses along the line and changes in wall thickness or diameter.

Contact us for a free trial or to learn more.