Probabilistic Assessment

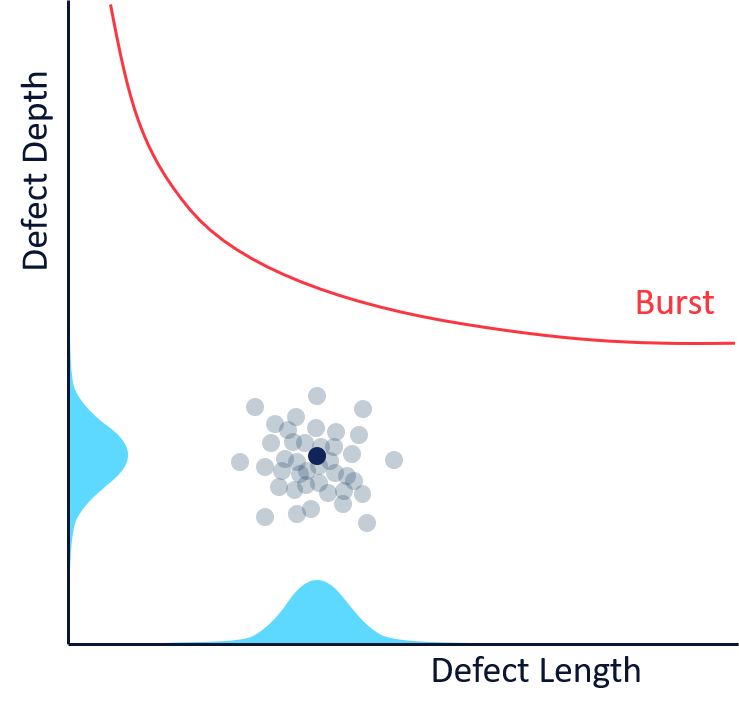

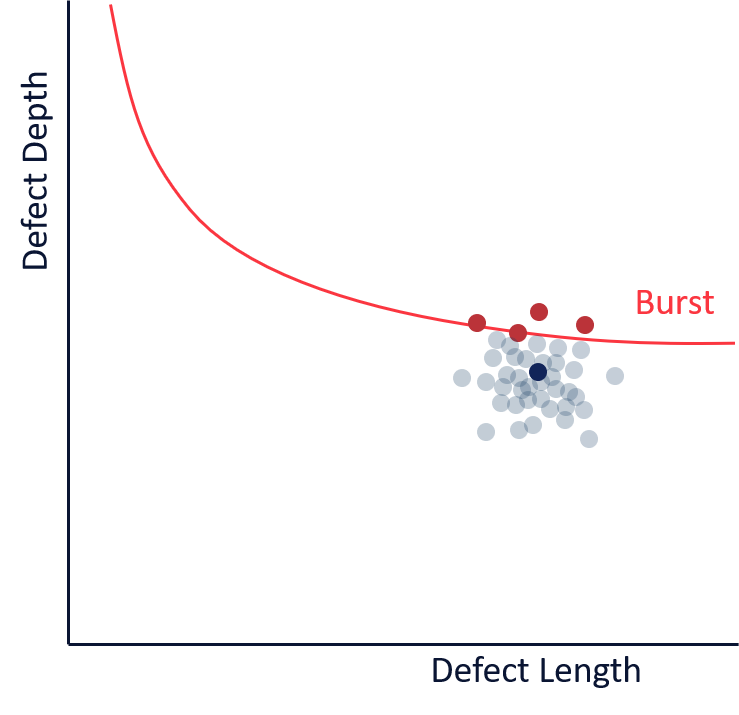

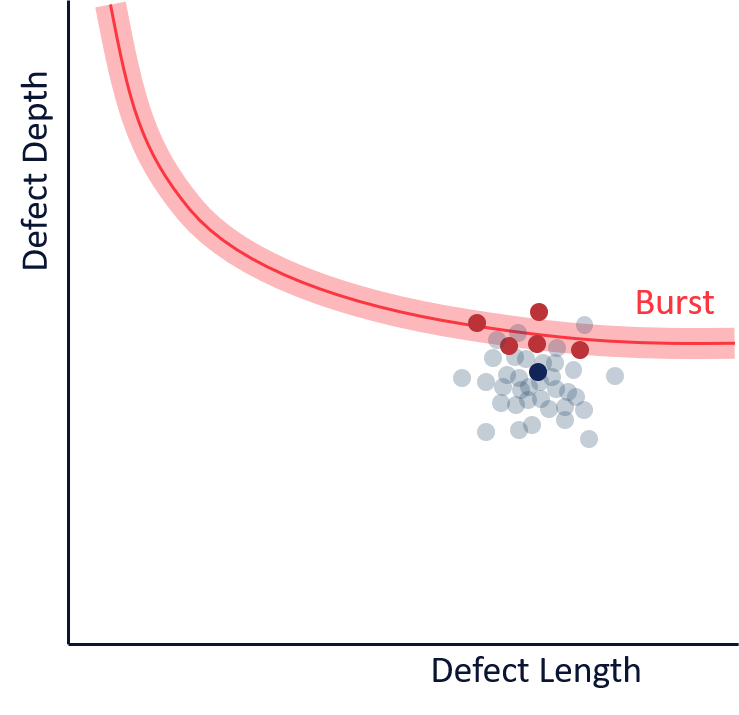

Stacking conservative assumptions when predicting the time-to-failure of corrosion, crack and dent defects on a pipeline or pressure equipment means that the remaining life of most defects is inevitably under-predicted. These conservative assumptions would typically include the defect size, pipe material properties and defect growth rates. Unfortunately, this approach can also be non‑conservative, for example, adding the ILI tool measurement error tolerance (at 80% certainty) to the reported defect depth, under-predicts the actual defect size 10% of the time.

Probabilistic defect failure probability models accurately account for all the sources of uncertainty and weigh the influence of each, so that, not only are the worst-case scenarios accounted for, but all possible cases are weighted by how likely they are to occur. These highly flexible models let you properly assess the effectiveness of mitigation strategies, including direct assessment, hydrostatic tests and your chosen ILI schedule.

The models fully account for:

variability in pipeline properties and dimensions

inspection tool measurement uncertainty

failure model accuracy

defect growth rates

To try probabilistic assessment for your pipelines, schedule a free assessment using your actual pipeline inspection data or contact us to learn more.